Manufacturing Capabilities

-

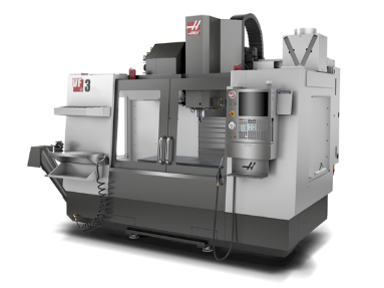

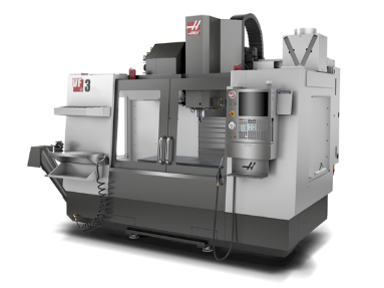

HAAS VF-3 CNC Mill

- 40”x20”x25” Travel

- 40 Taper

- 3-Axis

- 8.1k RPM

- 20 Tool Capacity

-

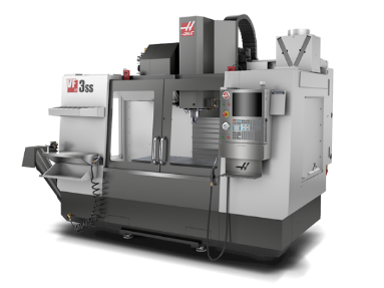

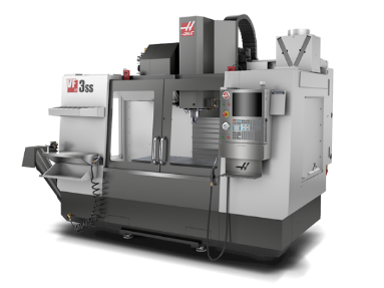

HAAS VF-3SS CNC Vertical Mill w/ HRT210

- 40”x20”x25”Travel

- 40 Taper

- 4-Axis

- 12k RPM

- 25+1 Tool Capacity

-

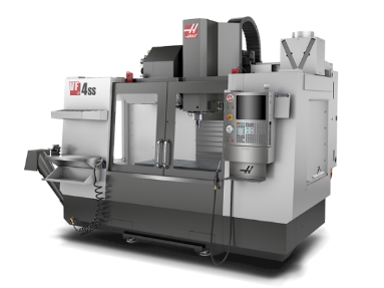

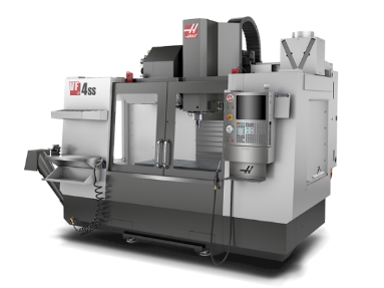

HAAS VF-4SS Vertical Mill w/ TRT160

- 50”x20”x25”Travel

- 40 Taper

- 5-Axis

- 12k RPM

- 25+1 Tool Capacity

-

HAAS VF-6SS CNC Vertical Mill w/TR210

- 64”x32”x30” Travel

- 40 Taper

- 5-Axis

- 12k RPM

- 25+1 Tool Capacity

-

HAAS UMC-750 5-Axis Mill

- 30”x20”x20”x24” Travel

- 40 Taper

- 5-Axis

- 8.1k RPM

- 40+1 Tool Capacity

-

HAAS EC-400 CNC Dual Pallet Horizontal Mill

- 22”x25”x22” Travel

- 40 Taper

- 4-Axis

- 8.1k RPM

- 30+1 Tool Capacity

-

HAAS ST-15Y Y-Axis Turning Center

- 8.3” Chuck Size

- 2.5” Through Hole Bar Capacity

- 4k RPM

- 20 Hp Power

-

Doosan Puma 2600SY-II Dual Spindle Turning Center

- 10” Chuck (Main Spindle)/ 8” Chuck (Sub-Spindle)

- 3.2” Through Hole Bar Capacity

- 14.8”D x 29.9”L Max Turning Capacity

- 4k/6k RPM

- 30Hp/20Hp Power

- 30+1 Tool Capacity

-

CNC 3-AXIS Router

Anderson Stratus Pro moving gantry 3-axis CNC router.Utilizes a 63” x 146” bed and is capable of 3D routing up to 14” inheight. High speed CNC operations at up

to 80 M/min at 24000 RPMs, powered by a 15 HP spindle. -

CNC 5-AXIS Router

CR Onsrud Model F146ES15 5-Axis Extreme Single table series CNC Router.Utilizes a 61”x 146” moving bed with fixed bridge, with 41” of Z-stroke travel.5-Axis 15 HP spindle, 24,000 RPM Double-armature with 120° A-Axis and +300°/-115° C-Axis

rotation. -

Spray/Adhesives Booth

Industrial open face paint/sanding booths with 3-stage filtration. Supply air is delivered through pressurized ceiling plenum located at the front of the booth via remotely located MAU. Exhaust air is evacuated through a 3-stage

blanket/pocket/HEPA filtered wall plenum located at the rear of the booth. -

Col-Met Spray Booths & Mixing Rooms

Booths: Custom down draft paint /

spray booth booth-mounted

Makeup Air Unit (MAU).Two

each booths are 168”(14’) x 288”(24’), with one additional booth at 168”(14’) x 336”(28’). =

Room: Paint mix room, non-pressurized.108”(9’) x 180”(15’). -

ASC Autoclave

ASC Econoclave, used for composite manufacturing. The autoclave has a usable interior space of 6’ dia x 16’ length. Max usable pressure is 200psi and max temp is 450F. It has 24 TC’s and 12 vacuum ports with pressure transducers. The system is run by ASC’s industry leading Composite Processing Control system for processing and data tracking.

-

Ultra High Pressure Platen Press

Top of the line platen press supporting large panels and very high pressures.

-

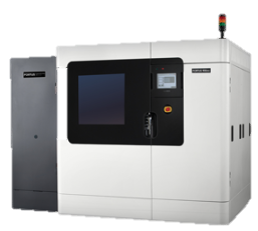

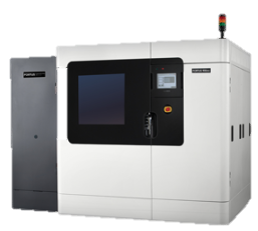

3D Printer for Additive Manufacturing

Stratasys Fortus 900mc 3D printer, with a max build envelope of (36 x 24 x 36 in.). Printer uses various types of ABS, up through ULTEM and PPSF thermoplastics. Currently we have the ability to print“ ASA as well as ULTEM 9085” material. Additionally a Makerbot Replicator 2 is used for smaller rapid prototypes and tooling

-

Harness Manufacturing

Laselec EasyWiring interactive harness assembly board utilizes software, engineering data, and a

75” screen to manufacture wiring harness using repeatable assembly methods. Board/display is capable to assemble hundreds of different harnesses on one assembly board. -

Flow Model 4800 Water Jet

60,000 PSI (60KSI) water jet with dynamic head and abrasive hopper feel. Cutting bed of48” x 96” x 8”, capable of extended length material beyond 96”.Utilizes closed loop recycler (Ebbco CLS-141-24K-HE) to minimize water use and waste. Used to cut metallic (soft and high hardness), ceramic, plastic, and composite materials.

-

Flow Model Mach 3 4020b Water Jet

87,000 PSI (87KSI) water jet with dynamic head and abrasive hopper feel. Cutting bed of77” x 156” x 8”.Used to cut metallic (soft and high hardness), ceramic, plastic, and composite materials.

-

Full Down Draft and Semi-Down Draft Spray Booths / Mix Room

Booths: Custom truck cross flow paint / spray booth with pressurized pant-leg supply and exhaust plenums and booth-mounted Makeup Air Unit (MAU).Each booth is 216”(18’) x 120”(10’) x 451”(37’-7”).

Room: Paint mix room, non-pressurized.90”(7’-6”) x 94”(7’-10”) x 144”(12’). -

Oven, Composite Curing

Electric oven, Despatch

Model PWC3-21-2, used for composite manufacturing. The oven has a stainless steel interior with circulation in a horizontal pattern for uniform heating.156 Cu Ft interior volume (52”x72”x72”), 37°C

(100°F) to 260°C (500°F) continuous operating temperature with multi-probe electronic data logger. -

Cleanrooms, Composites

Dedicated composites cleanroom with 288 Sq Ft interior volume (24’x12’x9’), with environmental control system for regulating consistent temperature and

humidity, variable airflow from 1000 to 2000 cfm with HEPA filtration with 99.97% efficiency at 0.3 micron -

Pull Test Cell

- Capable of load application in both horizontal plane (up to 7ft) and vertical plane (up to 12ft)

- NIST calibrated load cells with 20k ratings

- Measurement system is used in conjunction with Hydraulic tensile tests and impact tests